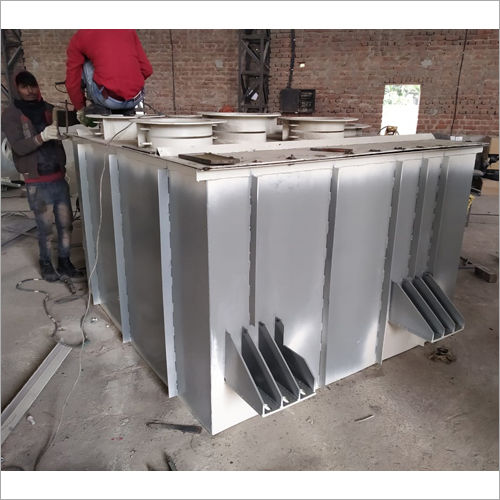

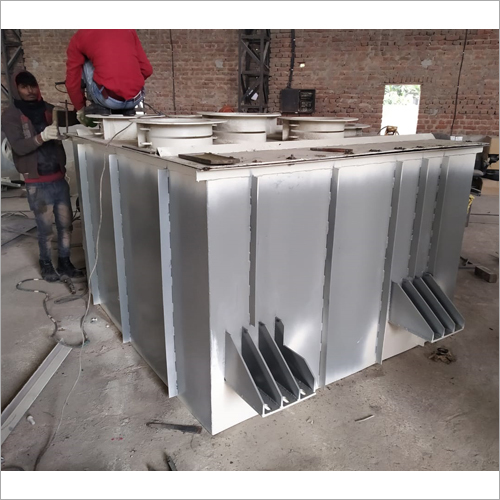

Industrial Chute

Price 5000 INR/ Piece

MOQ : 10 Pieces

Industrial Chute Specification

- Shape

- Curved/Rectangular

- Usage & Applications

- Material Handling, Bulk Material Flow, Factories, Industrial Conveyance

- Capacity

- Based on chute dimensions

- Diameter

- As per specification/design

- Noise Level

- Low

- Drive Type

- Gravity-driven

- Size

- Custom Sizes Available

- Features

- Robust Construction, Corrosion Resistant, Easy Installation

- Surface Finish

- Smooth/Glossy

- Product Type

- Industrial Chute

- Material

- Mild Steel

- Technology

- Welded Fabrication

- Power Source

- Manual/Gravity

- Pressure

- Atmospheric

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- Customized as per requirement

- Weight

- Variable (Depends on size/design)

- Color

- Silver/Grey

- Bend Type

- Available in Straight or Spiral

- Industry Standards

- Meets Industrial Safety Norms

- Operating Temperature

- Up to 120°C

- Maintenance

- Minimal

- Connection Type

- Flanged or Plain Ended

- Custom Fabrication

- Available

- Edge Protection

- Optional Rubber Lining

- Mounting Type

- Bolted/Fixed

- Opening Type

- Slotted/Funnel

- Compatibility

- Suitable for Belt/Chain Conveyors

- Discharge Angle

- As per material flow requirement

Industrial Chute Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 15 Days

About Industrial Chute

Stone Crushing Machine Parts are the widely used parts in stone crusher machines. Finest of raw material and progressive machinery is used in fabricating these as per the industrial laid norms and standards. Stone Crushing Machine Parts can be availed from us at highly affordable prices among that of our competitors.

Custom-Engineered for Versatility

Our Industrial Chutes are custom-fabricated to suit your material flow needschoose from slotted or funnel openings and straight or spiral bends. Each chute is tailored in dimensions, diameter, and discharge angle, ensuring optimal alignment for your conveyance system. With a smooth, powder-coated surface and corrosion-resistant build, this chute integrates seamlessly into belt or chain conveyor setups, supporting a wide range of applications.

Robust Performance and Low Maintenance

Constructed from premium mild steel using advanced welded fabrication, our chutes are designed for durability and low noise. The sturdy, powder-coated finish and optional rubber edge lining provide added protection against wear, abrasion, and corrosion. With minimal maintenance needs, the chutes offer reliable performance even at temperatures up to 120C, making them ideal for busy factory and industrial environments.

Safety-First, Easy Installation

Prioritizing industrial safety, all chutes meet relevant safety norms and feature easy installationselect flanged or plain-ended connections to match your infrastructure. The lightweight, gravity-driven design keeps operation simple, while robust mounting (bolted or fixed) ensures stability and security during use. Benefit from a solution that is both user-friendly and meets the rigorous demands of modern industrial material handling.

FAQs of Industrial Chute:

Q: How do I select the right discharge angle for my industrial chute?

A: The discharge angle is customized based on your specific material flow requirements, which ensures efficient movement through the chute. Our engineering team can guide you in determining the optimal angle according to the nature of the material and your system layout.Q: What benefits does the optional rubber lining provide for edge protection?

A: The optional rubber lining offers extra protection against wear and abrasion, extending the service life of the chute. It also helps reduce noise and impact during material discharge, making it ideal for high-volume or abrasive material handling.Q: Where can these industrial chutes be installed and used?

A: These chutes are mainly installed in factories and industrial plants for applications like bulk material flow, material handling, and industrial conveyance. They are compatible with belt or chain conveyors and can be adapted to other material flow systems based on requirements.Q: What is the process for custom fabrication and ordering?

A: You can request customized chute dimensions, shape, bends, and other features to perfectly suit your project. After consultation and approval of specifications, we fabricate the chute to your needs and ensure it meets industrial safety standards before delivery.Q: What kind of maintenance does the chute require?

A: Our chutes are designed for minimal maintenance. Routine cleaning and occasional inspection of the surface finish and edge protection (if installed) are recommended to ensure consistent performance and longevity.Q: How does the bolted or fixed mounting type benefit industrial applications?

A: Bolted or fixed mounting ensures stable and secure installation, which is especially important in high-throughput or vibration-prone environments. This makes the chute easy to install, align, and reposition as needed within your system.Q: What advantages does a gravity-driven system offer in material handling chutes?

A: A gravity-driven chute eliminates the need for external power sources, reducing energy consumption and operational costs. It provides smooth, reliable movement of materials with minimal intervention, enhancing safety and efficiency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Crusher Machine Parts Category

Conveyor Part

Price 5000 INR / Piece

Minimum Order Quantity : 10 Pieces

Diameter : As per Part

Product Type : Other, Conveyor Part

Capacity : Heavy Duty

Weight : Depends on Size

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free